Daily Plant Checks: How Digital Tools Improve Safety and Accountability

Why Daily Plant Checks Are Critical

On construction sites, plant equipment—from excavators and telehandlers to generators and lifting gear—is the backbone of operations. Daily plant checks are a legal and practical necessity, ensuring that machinery is safe to operate and fully functional before use. Skipping or improperly documenting these checks can result in accidents, equipment failure, or costly downtime.

Daily checks also play a vital role in regulatory compliance. Under PUWER (Provision and Use of Work Equipment Regulations) and LOLER (Lifting Operations and Lifting Equipment Regulations), operators must inspect equipment regularly, identify faults, and ensure machinery is safe for use. Paper-based systems make compliance difficult to track and audit, often leading to missing or incomplete records.

Digital tools like workMule transform daily plant checks, making them faster, more accurate, and instantly accessible across teams. By connecting inspections, fault reporting, and maintenance records, construction managers can improve safety, accountability, and operational efficiency.

What a Daily Plant Check Involves

A thorough daily plant check covers multiple areas:

- Visual Inspection: Look for signs of damage, leaks, wear, or corrosion.

- Functional Tests: Check brakes, steering, hydraulic functions, and limit switches.

- Safety Devices: Confirm alarms, emergency stops, guards, and other protective features are operational.

- Fluid Levels: Ensure fuel, oil, coolant, and hydraulic fluids are within safe ranges.

- Tires, Tracks, and Undercarriage: Inspect for wear, punctures, or damage.

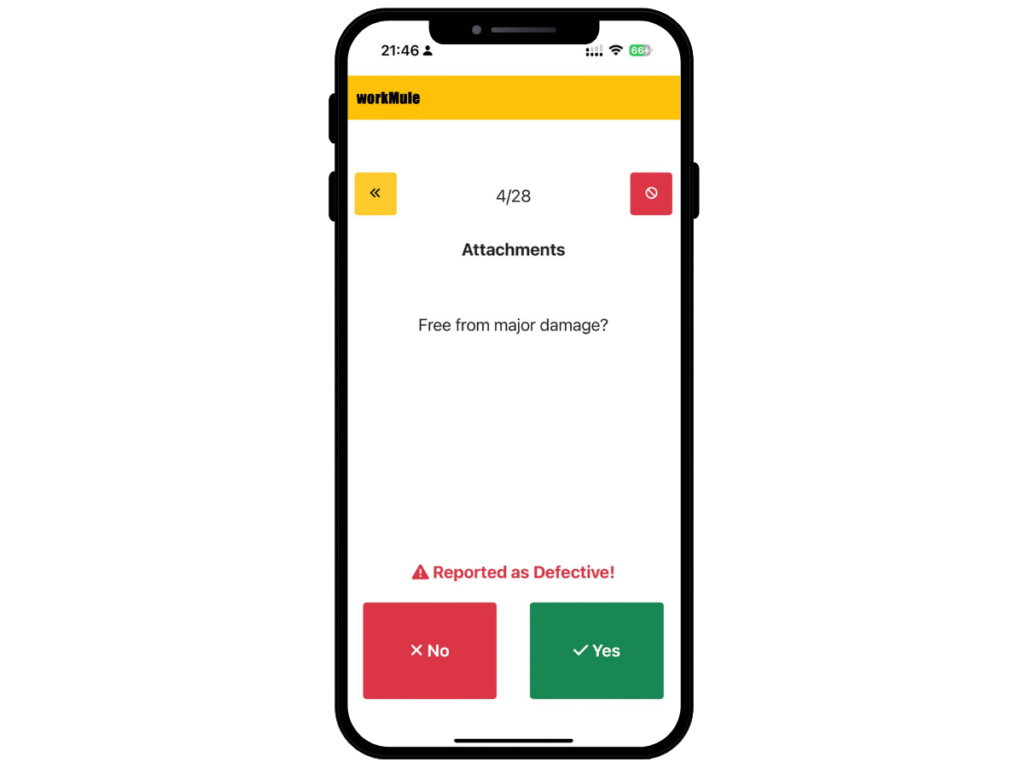

- Attachments and Lifting Gear: Verify chains, slings, hooks, and other accessories are in good condition.

- Documentation: Record any defects, maintenance needs, or unusual observations.

When performed digitally, these checks are tracked in real time, reducing human error and ensuring every item is addressed before equipment is used. workMule’s platform allows teams to customise checklists for each asset type, making inspections quick and precise.

Digital Daily Checks vs Paper-Based Systems

Traditional paper-based daily checks are prone to inefficiencies and risk:

- Lost or damaged forms: Paper can be misplaced, misfiled, or illegible.

- Delayed reporting: Supervisors may not know about a defect until hours or days later.

- Incomplete inspections: Items can be skipped or overlooked, leaving hazards unaddressed.

- Audit difficulties: Compiling paper records for compliance checks is time-consuming and error-prone.

Digital daily plant checks solve these problems by offering a centralised, cloud-based system. Go paperless with inspections to capture every check in real time, with photos, notes, and time stamps. Supervisors can monitor site-wide compliance instantly and follow up on defects before they become incidents.

Benefits of Digital Daily Plant Checks

Switching to digital daily checks delivers measurable benefits for construction teams:

Enhanced Safety: Identifying and addressing defects before operation reduces accidents.

Real-Time Accountability: Supervisors can see who completed each check and when.

Audit-Ready Records: Time-stamped digital logs satisfy PUWER and LOLER compliance requirements.

Integration with Maintenance: Faults reported during checks can trigger automated maintenance workflows.

Consistency Across Teams: Standardised digital checklists ensure every operator follows the same process.

Reduced Downtime: Early detection of faults allows faster repairs, preventing unexpected breakdowns.

By linking daily plant checks to plant inspections and other site workflows, construction managers can create a fully integrated safety and maintenance system.

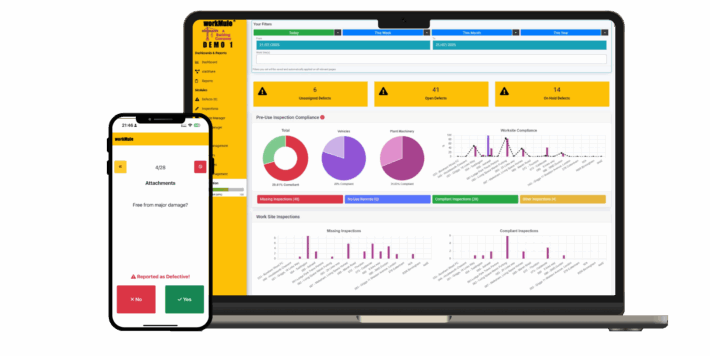

How workMule Supports Daily Plant Checks

workMule is designed for construction and plant hire companies who need practical, real-time solutions for compliance and safety. Key features include:

- Customisable checklists: Tailored for excavators, telehandlers, generators, and more.

- Offline functionality: Conduct checks in remote or low-signal locations.

- QR code scanning: Access the correct checklist instantly for each asset.

- Real-time defect reporting: Any issue is logged and escalated automatically.

- Secure digital records: Inspection history and certificates stored in one centralised platform.

- Integration with existing systems: workMule works with your other software through integrations, connecting inspections with maintenance, asset management, and reporting workflows.

With workMule, daily checks are no longer a paperwork chore—they become a live, actionable part of operations.

Best Practices for Implementing Digital Daily Plant Checks

To maximise the benefits of digital daily checks, construction managers should:

- Train operators on the purpose behind each check and how to use the digital system.

- Schedule automated reminders to ensure inspections are never missed.

- Regularly review inspection data to identify recurring faults or safety trends.

- Link defect reporting directly to maintenance workflows for faster resolution.

- Use dashboards to monitor completion rates and ensure accountability across sites.

Following these best practices encourages a proactive safety culture, where compliance is part of daily routines rather than an afterthought.

Tangible Benefits for Construction Teams

Implementing digital daily plant checks provides:

- Safer sites with fewer equipment-related accidents

- Reduced unplanned downtime and faster repairs

- Centralised, traceable compliance records for audits

- Improved accountability for operators and supervisors

- Integration with inspections, fault reporting, and maintenance planning

- Insights for data-driven decision-making on equipment use and lifecycle management

By digitising daily checks, construction teams save time, reduce errors, and maintain complete visibility over all plant assets.

Conclusion: Make Daily Plant Checks Simple and Effective

Daily plant checks are a cornerstone of safety, compliance, and operational efficiency on construction sites. Paper forms slow down processes, create risk, and make audits harder. Digital platforms like workMule simplify daily checks, link inspections with maintenance, and provide real-time, audit-ready records.

By embedding daily plant checks into everyday operations, construction teams can keep equipment safe, reduce downtime, and enhance accountability across every site.

👉 Book a demo today to see how workMule can help your team digitise daily plant checks and streamline compliance across your fleet.