Equipment Fault Reporting Made Simple: Reduce Downtime on Site

Why Fast Equipment Fault Reporting Matters

On construction sites, machinery is constantly in use—from excavators and telehandlers to generators and lifting equipment. When a piece of equipment fails unexpectedly, it can halt work, put staff at risk, and lead to expensive delays. Faults that go unreported or unnoticed often compound problems, turning small maintenance issues into major breakdowns.

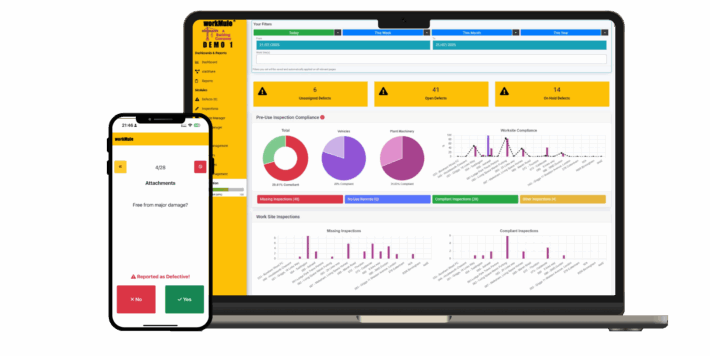

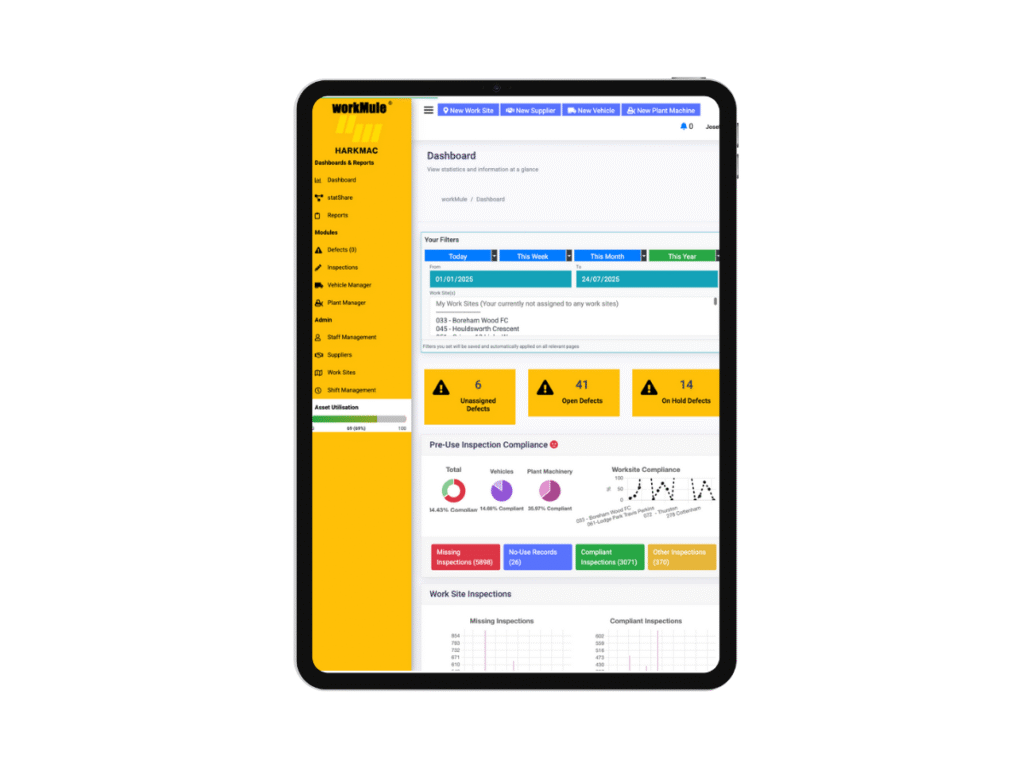

Digital equipment fault reporting provides a proactive solution, allowing operators to flag defects immediately. Platforms like workMule make it simple to log faults, notify maintenance teams, and track resolution—all in real time. By replacing paper-based fault reports with a digital system, construction companies gain speed, accuracy, and oversight, ensuring downtime is minimised.

Common Equipment Faults on Construction Sites

Some of the most common issues that need reporting include:

- Hydraulic leaks or pressure loss in machinery

- Broken or worn lifting accessories such as slings, chains, or hooks

- Engine or fuel system problems

- Malfunctioning safety systems like emergency stops or limit switches

- Electrical faults in tools or powered equipment

Even minor faults can escalate quickly if left unchecked. By integrating fault reporting with pre-use inspections and daily plant checks, managers can identify patterns and prevent recurring problems before they impact productivity.

Additionally, using digital tools helps ensure faults are captured consistently across all shifts and teams. Whether a junior operator spots a minor issue on a telehandler or a site supervisor notices a generator fault, workMule ensures that every report is logged, assigned, and tracked in a centralised system. This removes uncertainty about whether faults have been communicated or acted upon, fostering accountability and clarity on site.

The Advantages of Digital Fault Reporting

Digital fault reporting offers several clear benefits over traditional paper forms:

- Instant notifications: Maintenance teams are alerted immediately when a fault is logged.

- Traceable records: Every reported defect is time-stamped, linked to the asset, and stored securely for audits.

- Integration with inspections: Faults can be flagged directly from digital pre-use checklists during daily plant inspections.

- Reduced downtime: Quick communication between operators and maintenance ensures repairs happen sooner.

- Data-driven maintenance planning: Analysis of fault reports helps identify recurring problems, allowing teams to plan preventive maintenance rather than reactive fixes.

Digital reporting also helps construction managers prioritise critical equipment. For example, a crane with a reported defect can automatically trigger higher-priority maintenance than a minor issue with a generator, reducing the risk of work stoppages.

How workMule Simplifies Fault Reporting

workMule is built to make fault reporting intuitive and actionable for construction teams:

- Asset-based reporting: Log defects against specific machinery, tools, or lifting equipment.

- Offline functionality: Faults can be reported even in low-signal or remote sites.

- Photo and video uploads: Capture evidence of faults for clearer communication and accountability.

- Real-time escalation: Urgent faults can automatically alert supervisors or maintenance teams.

- Integration with other systems: workMule connects with broader integrations to create a seamless workflow.

By connecting fault reporting with pre-use inspections, daily checks, and maintenance records, teams can streamline operations and prevent costly downtime across all sites.

Best Practices for Fault Reporting

To maximise the benefits of digital fault reporting, construction teams should:

- Train operators to report even minor defects immediately, rather than waiting for the next inspection.

- Link fault reporting with scheduled maintenance tasks to prioritise repairs.

- Use dashboards to monitor fault resolution times and recurring issues.

- Integrate photo evidence with inspection records for full transparency.

- Regularly review fault trends to improve equipment reliability and safety.

By combining fault reporting with digital pre-use inspections and daily plant checks, construction firms can ensure compliance, safety, and efficiency go hand in hand. workMule makes it easy to go paperless with inspections while maintaining full visibility over all reported issues.

Tangible Benefits for Construction Teams

Digital equipment fault reporting delivers measurable results:

- Reduced downtime and faster equipment repairs

- Improved site safety through immediate defect visibility

- Centralised and secure records for audits and compliance

- Increased accountability for operators and supervisors

- Better-informed maintenance and replacement decisions

- Streamlined workflows linking inspections, faults, and maintenance

With every defect logged, tracked, and resolved in real time, construction managers can maintain productivity, keep workers safe, and extend the life of their machinery.

Conclusion: Make Fault Reporting Fast, Simple, and Effective

Paper-based fault logs are slow, prone to errors, and difficult to track. By adopting workMule’s digital platform, construction teams can streamline fault reporting, integrate it with daily inspections, and reduce costly downtime across all sites.

Every defect becomes visible, actionable, and traceable, helping managers focus on completing projects safely and efficiently.

👉 Book a demo today to see how workMule can help your team simplify equipment fault reporting and improve site efficiency.