Lockout Tagout Procedures: A Step-by-Step Guide for Safe Equipment Handling

Why Lockout Tagout Procedures Matter

Construction and industrial sites rely on heavy machinery, tools, and equipment every day. When maintenance or repairs are required, energy sources such as electricity, hydraulics, or compressed air can pose serious risks if machines are inadvertently activated. Lockout Tagout (LOTO) procedures exist to prevent these accidents, protecting operators, maintenance teams, and contractors.

LOTO procedures are a critical component of work equipment safety regulations, ensuring that machinery is isolated from energy sources during service or maintenance. Failing to implement proper LOTO procedures can result in serious injury, regulatory breaches, and operational downtime.

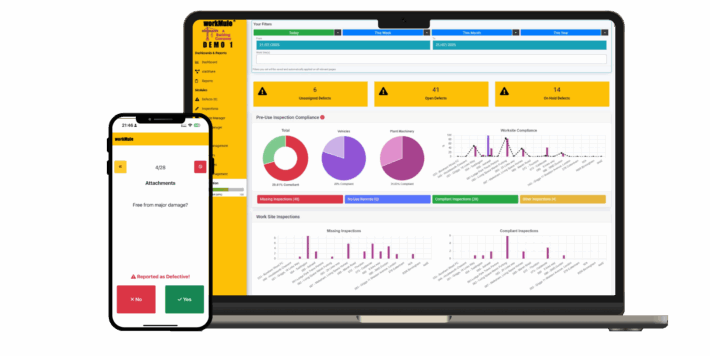

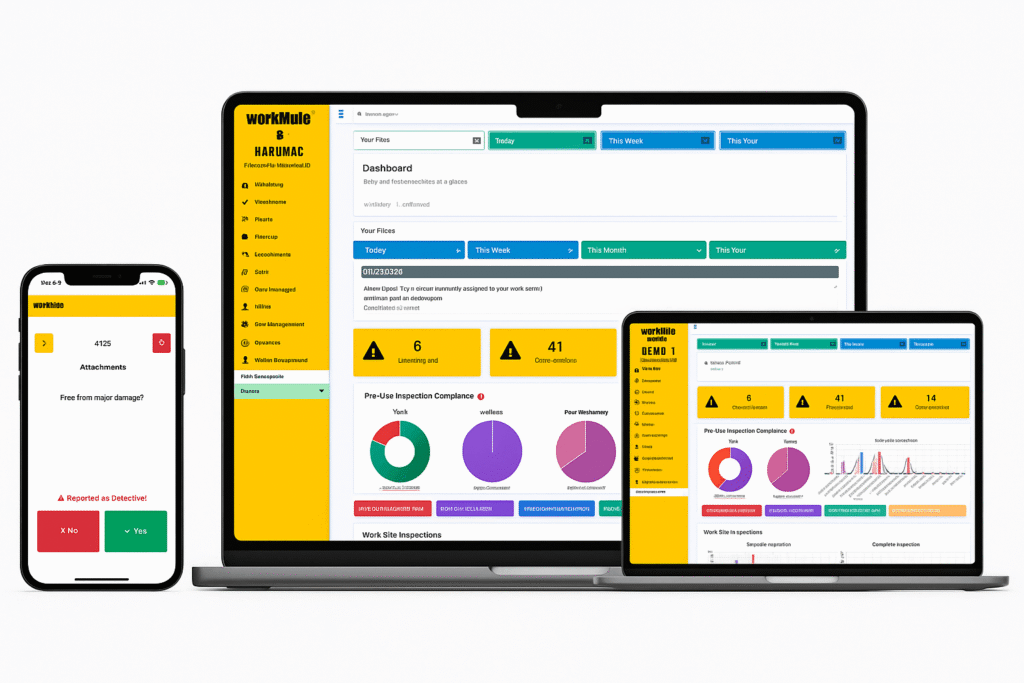

Digital platforms like WorkMule help construction teams implement, monitor, and record LOTO procedures efficiently. By moving away from paper forms to digital workflows, compliance becomes seamless, audit-ready, and traceable across multiple sites.

What Lockout Tagout Procedures Involve

A robust LOTO process typically involves the following steps:

- Preparation: Identify all energy sources connected to the equipment and understand the hazards involved.

- Shutdown: Turn off the machinery according to manufacturer instructions and isolate energy sources.

- Lockout: Apply locks and tags to secure energy-isolating devices, preventing accidental activation.

- Verification: Confirm that the equipment is completely de-energised by attempting to operate controls in a safe manner.

- Maintenance or Service: Perform the required work safely.

- Release and Restart: Remove locks and tags, restore energy, and notify operators that the equipment is ready for use.

Digital tools allow operators to record each step, attach photos, and assign accountability to specific personnel, ensuring compliance and traceability. WorkMule’s system integrates LOTO checks with plant inspections and daily safety routines, so every procedure is documented.

The Drawbacks of Paper-Based LOTO Procedures

Many construction teams still rely on paper forms to track LOTO processes. This approach has several drawbacks:

- Lost records: Paper forms are easily misplaced or damaged.

- Limited visibility: Supervisors cannot monitor LOTO compliance in real-time.

- Manual errors: Steps can be skipped or incorrectly documented.

- Inefficient audits: Collecting and reviewing physical forms for compliance checks is slow and time-consuming.

Switching to digital LOTO procedures eliminates these problems. By using digital inspection checklists, teams ensure every step is completed accurately, stored securely, and instantly accessible to management.

Benefits of Digital LOTO Procedures

Implementing digital LOTO workflows brings multiple advantages for construction teams:

- Enhanced Safety: Digital procedures ensure no step is missed, reducing the risk of accidents during maintenance.

- Real-Time Tracking: Supervisors can see who performed each lockout and when, improving accountability.

- Audit-Ready Compliance: Digital logs provide instant evidence of compliance with PUWER and other safety regulations.

- Integration with Plant Inspections: Linking LOTO procedures to plant inspections ensures that every asset’s safety history is complete.

- Reduced Downtime: Faults or energy isolation issues identified during LOTO checks are flagged immediately, enabling faster maintenance resolution.

- Centralised Records: Every lockout event, inspection, and checklist is stored in one secure platform, accessible for multiple sites.

How WorkMule Supports LOTO Compliance

WorkMule is built specifically for construction and plant hire teams to manage LOTO procedures digitally alongside inspections and safety workflows. Key features include:

- Customisable checklists: Tailor LOTO steps for different machines and energy sources.

- Offline access: Perform procedures even in low-signal or remote areas.

- QR code scanning: Access the correct LOTO checklist for each piece of equipment instantly.

- Real-time fault reporting: Any hazards or non-compliance issues are escalated immediately.

- Integration with existing systems: WorkMule works alongside other project management or maintenance software through integrations.

By combining LOTO procedures with digital plant inspections and paperless workflows, teams gain a connected safety system that reduces risk and keeps all records organised.

Best Practices for Rolling Out Digital LOTO Procedures

To make the most of digital LOTO workflows, construction managers should:

- Train staff on the purpose behind each step, not just how to tick boxes.

- Schedule automated reminders to prevent missed procedures.

- Monitor completion rates through dashboards and real-time reports.

- Connect LOTO procedures directly to defect reporting and maintenance workflows.

- Regularly review data to identify recurring issues or process improvements.

This proactive approach ensures that compliance becomes part of everyday operations rather than a reactive task.

Tangible Benefits for Construction Teams

Implementing digital LOTO procedures delivers measurable benefits:

- Safer work environments with fewer energy-related incidents

- Reduced downtime from faster fault resolution

- Centralised, accessible audit records

- Improved accountability across operators and maintenance teams

- Streamlined integration with inspections, defect reporting, and maintenance scheduling

- Data-driven insights to optimise asset management

By documenting every lockout, verification, and service, teams reduce errors, prevent accidents, and improve overall efficiency.

Conclusion: Modernising Lockout Tagout for Safer Sites

LOTO procedures are non-negotiable for safe equipment handling, but managing them on paper is cumbersome and risky. Digital tools like WorkMule simplify compliance, integrate with daily inspections, and make audits effortless.

By embedding LOTO procedures into your daily workflows, you create a safer, more accountable, and efficient construction site. Every lockout is traceable, every fault is visible, and every site is better prepared to operate safely.

👉 Book a demo today to see how WorkMule can help your team digitise lockout tagout procedures and simplify compliance across your fleet.