Track, Inspect and Manage Your Tools

All in One Place

From grinders and saws to hand tools and battery kits, workMule makes inspecting small tools fast, consistent and fully traceable across sites.

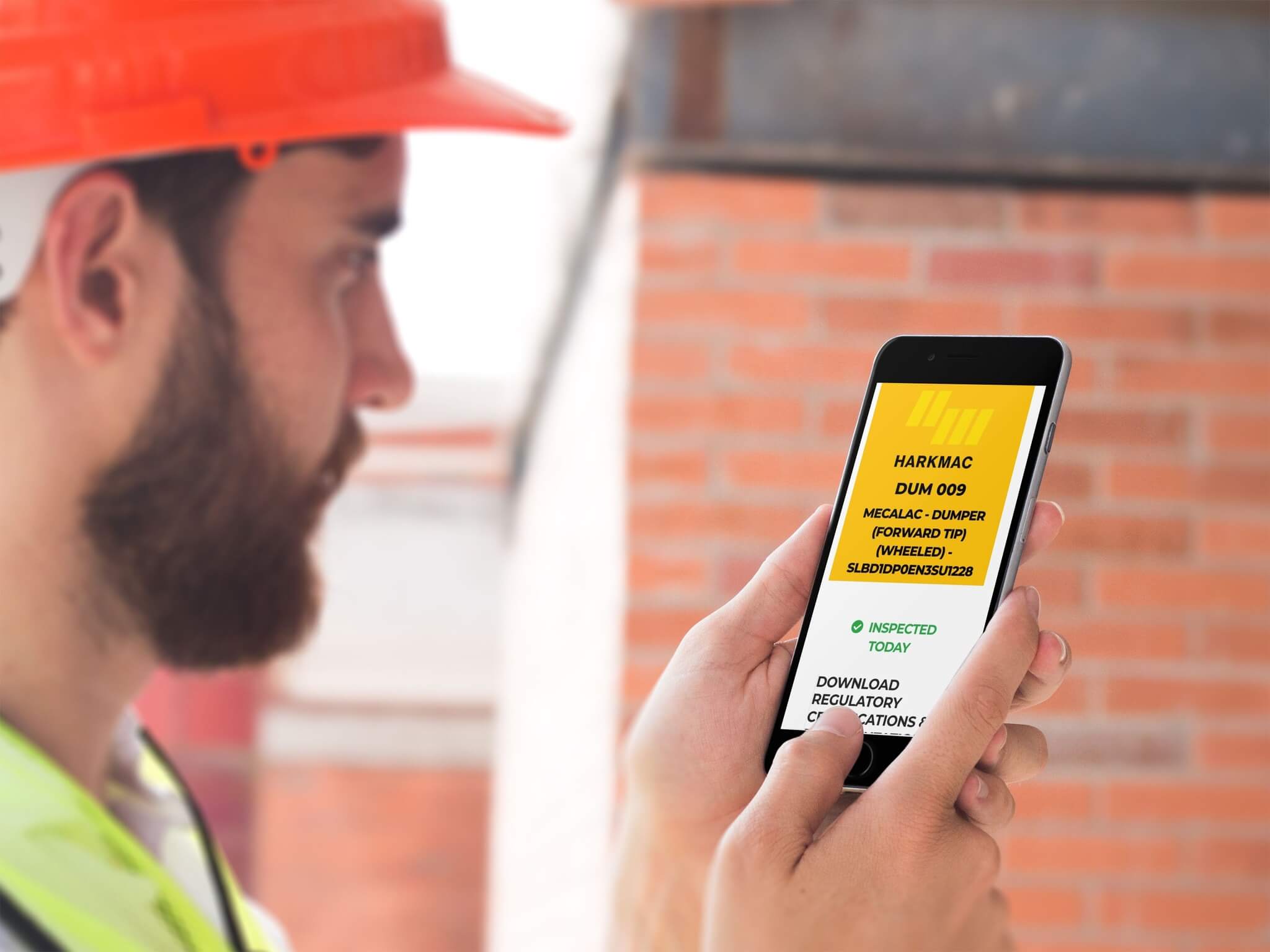

Plant Inspections

Why Digital Inspections for Tools?

Small tools often slip through the cracks — uninspected, misplaced or damaged. With workMule, every tool has a digital record, and every check is easy, repeatable and logged for compliance.

-

Scan barcodes or search tools to begin inspections

-

Perform guided checks in seconds

-

Flag defects and assign repairs

-

Access full inspection history at any time

Whether it’s battery kits, grinders or drills, you’ll always know what’s been checked, what’s in use, and what needs attention.

Benefits

Key Benefits

-

Eliminate guesswork with tracked inspections

-

Improve tool safety and reliability across your workforce

-

Cut down tool loss with digital records and sign-outs

-

Ensure each tool is safe, functional and accounted for

Features Built for Tools

-

Barcode scan or serial search to locate tools

-

Assign tools to operatives or sites

-

Log visual checks and test results

-

Add notes or photos for damaged items

-

View last-used and last-inspected history

-

Create audit reports by site or timeframe

Results You Can Expect

0

%

90% reduction in lost or untracked tools

0

%

100% inspection visibility across all kits

0

%

50% fewer tool-related incidents on site

What Clients Say

How It Works.

Operator scans tool or selects from list

Performs visual and functional checks

Adds any comments, flags issues

Signs off and submits inspection

Admin dashboard updates with inspection date and defect logs

Designed for Field Teams

workMule keeps inspections consistent even across fast-moving sites. No more relying on memory, whiteboards or lost sign-out sheets. Now you’ve got a live system for your small tools.

Offline support lets users inspect even without signal — perfect for remote or underground workspaces.